Building a DIY Sandblasting Cabinet

Building your own sandblasting cabinet can be a rewarding project, offering a significant cost saving compared to purchasing a pre-made one. It allows you to customize the size and features to meet your specific needs, and you gain the satisfaction of creating something useful with your own hands.

Benefits of a DIY Sandblasting Cabinet

A DIY sandblasting cabinet offers several advantages:

- Cost Savings: Building your own cabinet can save you a substantial amount of money compared to buying a pre-made one.

- Customization: You can tailor the size, features, and materials to your specific requirements and workspace.

- Learning Experience: The project provides a hands-on learning opportunity and a sense of accomplishment.

Materials and Tools

To build a basic sandblasting cabinet, you will need the following materials and tools:

- Cabinet Structure:

- Plywood or MDF (for the main body)

- Metal angle brackets or other structural supports

- Wood screws or metal fasteners

- Sandblasting Chamber:

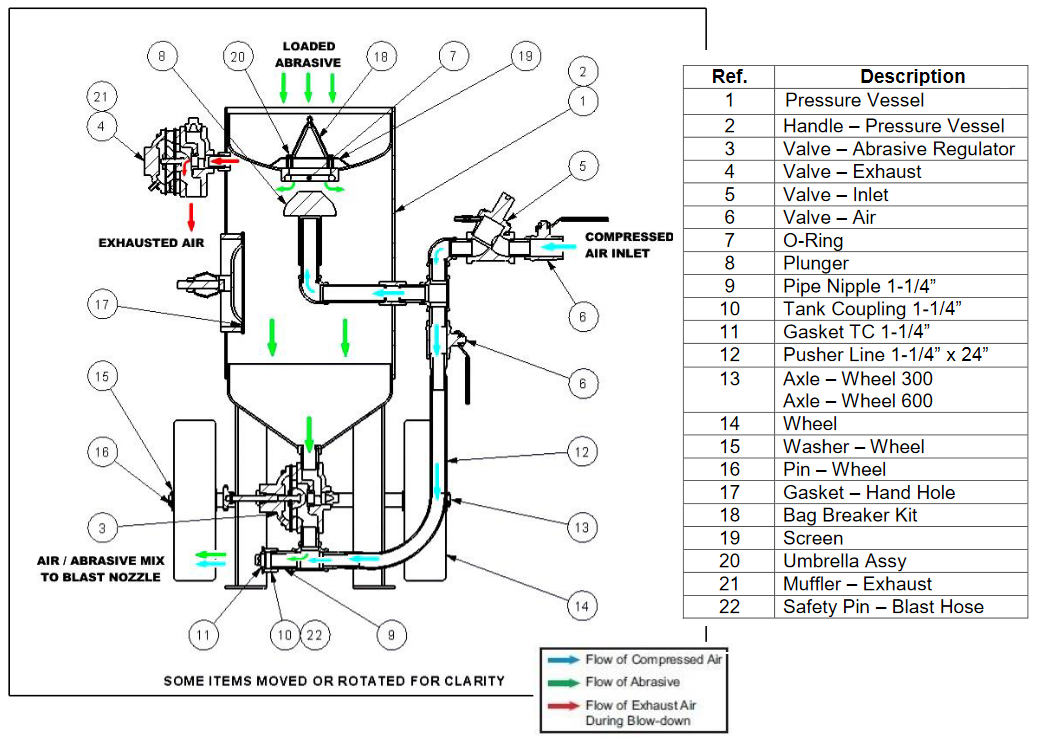

- Pressure vessel (optional, for higher pressure applications)

- Modified trash can (for a simple design)

- Custom-built structure (for a more advanced design)

- Sandblasting Equipment:

- Sandblasting gun

- Air compressor (with a minimum of 5 CFM at 90 PSI)

- Sandblasting media (e.g., silica sand, glass beads, walnut shells)

- Air hose and fittings

- Pressure regulator and gauge

- Safety goggles and respirator

- Other Materials:

- Silicone sealant

- Paint (optional, for finishing the cabinet)

- Window or viewing port (optional)

- Tools:

- Saw (circular, jigsaw, or table saw)

- Drill and drill bits

- Screwdriver

- Measuring tape and level

- Clamps

- Safety gloves and work boots

Construction Steps

Building a basic sandblasting cabinet involves the following steps:

- Design and Planning: Determine the size and shape of your cabinet, considering the size of the objects you intend to sandblast. Choose the type of sandblasting chamber (pressure vessel, trash can, or custom-built) that suits your needs and budget. Sketch a detailed plan of your cabinet, including all dimensions and components.

- Cabinet Construction: Cut the plywood or MDF panels according to your plan. Assemble the cabinet using wood screws or metal fasteners. Ensure the cabinet is structurally sound and can withstand the pressure of the sandblasting process.

- Sandblasting Chamber Installation: Install the sandblasting chamber inside the cabinet. If using a pressure vessel, ensure it is securely mounted and properly sealed. If using a trash can, cut a hole in the top for the sandblasting gun and seal the edges with silicone sealant.

- Air and Media Connections: Install the air hose and fittings to connect the air compressor to the sandblasting gun. Create an opening for the sandblasting media to be fed into the chamber.

- Viewing Port and Lighting: If desired, install a window or viewing port to observe the sandblasting process. Add lighting inside the cabinet for better visibility.

- Finishing and Testing: Finish the cabinet with paint (optional) for a professional look. Test the sandblasting system by running the air compressor and checking for leaks. Ensure all safety precautions are in place before operating the cabinet.

Safety Precautions

Sandblasting is a hazardous process, and it is essential to take all necessary safety precautions.

Always wear safety goggles and a respirator to protect your eyes and lungs from dust and debris.

Use appropriate gloves to protect your hands.

Avoid inhaling sandblasting media.

Keep the sandblasting cabinet well-ventilated.

Never operate the sandblasting cabinet without proper training and safety equipment.

Different Cabinet Designs

#### Pressure Vessel Design

This design utilizes a pressure vessel as the sandblasting chamber, offering high pressure and a larger capacity for larger projects. The pressure vessel needs to be properly rated for the intended pressure and must be securely mounted inside the cabinet.

#### Modified Trash Can Design

This simple and cost-effective design uses a modified trash can as the sandblasting chamber. The trash can needs to be sealed properly to prevent dust leakage, and a hole needs to be cut in the top for the sandblasting gun.

#### Custom-Built Structure

This design allows for maximum customization and flexibility. You can design and build a custom-built structure using materials like metal or acrylic to create a durable and aesthetically pleasing cabinet.

Sandblasting Techniques and Applications: Diy Sand Blast Cabinet

Sandblasting is a versatile technique that utilizes high-pressure air to propel abrasive particles against a surface, effectively removing material and creating desired finishes. This process finds applications in various industries, from metalworking and manufacturing to artistic endeavors.

Sandblasting Media

The choice of sandblasting media depends on the desired outcome and the material being treated. Each media type possesses unique characteristics that influence its effectiveness and suitability for specific applications.

- Silica Sand: This common and cost-effective media is known for its aggressive nature, making it suitable for heavy-duty cleaning, removing rust, and preparing surfaces for painting. However, its use is becoming increasingly restricted due to its potential health hazards, including silicosis, a lung disease caused by inhaling silica dust.

- Glass Beads: Glass beads offer a gentler approach to sandblasting, leaving a smoother finish compared to silica sand. They are frequently used for cleaning delicate surfaces, deburring metal parts, and creating a frosted effect on glass.

- Walnut Shells: Walnut shells provide a unique combination of cleaning power and surface preservation. They are particularly effective for removing paint and coatings without damaging the underlying material. Their organic nature makes them a more environmentally friendly option compared to silica sand.

Safe Operation of a Sandblasting Cabinet

Sandblasting can be hazardous if not performed correctly. Proper safety precautions are essential to minimize the risk of injury and exposure to harmful particles.

- Protective Attire: Wear a respirator mask certified for sandblasting, safety glasses, gloves, and a long-sleeved shirt and pants to protect your skin from abrasive particles.

- Ventilation: Ensure adequate ventilation in the work area to prevent the buildup of dust and harmful fumes. A well-ventilated sandblasting cabinet is crucial for safety.

- Handling of Media: Store sandblasting media in sealed containers and handle them with care to avoid spills and dust generation.

- Regular Maintenance: Regularly inspect the sandblasting cabinet and its components for wear and tear, ensuring its proper functioning and safety.

Applications of Sandblasting, Diy sand blast cabinet

Sandblasting finds a wide range of applications across various industries and crafts, enabling surface preparation, cleaning, and decorative finishes.

- Cleaning Metal Parts: Sandblasting effectively removes rust, paint, and other contaminants from metal parts, preparing them for welding, painting, or other processes.

- Surface Preparation for Painting: Sandblasting creates a rough surface, providing excellent adhesion for paint, ensuring a durable and long-lasting finish.

- Etching Glass: Sandblasting can etch designs and patterns onto glass, creating frosted or opaque effects for decorative purposes.

- Creating Decorative Finishes: Sandblasting can achieve unique finishes on various materials, including wood, metal, and glass, adding texture and depth to surfaces.

Examples of Sandblasting Projects

The versatility of sandblasting allows for a wide array of projects, from restoration to customization and artistic expression.

- Restoring Antique Furniture: Sandblasting can remove layers of paint, varnish, and grime from antique furniture, revealing the original wood grain and restoring its beauty.

- Customizing Tools: Sandblasting can be used to personalize tools by etching names, logos, or designs onto their surfaces.

- Creating Unique Artwork: Artists utilize sandblasting to create intricate designs on glass, metal, and other materials, resulting in unique and visually appealing artwork.

Comparison of Sandblasting Media

| Media Type | Pros | Cons | Suitable Applications |

|---|---|---|---|

| Silica Sand | Cost-effective, aggressive cleaning power | Health hazards, can damage delicate surfaces | Heavy-duty cleaning, rust removal, surface preparation for painting |

| Glass Beads | Gentle on surfaces, smooth finish | Less aggressive than silica sand | Cleaning delicate surfaces, deburring metal parts, frosting glass |

| Walnut Shells | Environmentally friendly, preserves surfaces | Less aggressive than silica sand, higher cost | Removing paint and coatings, cleaning wood and metal surfaces |

Safety Considerations and Best Practices

Sandblasting, while a powerful and versatile technique, poses significant safety risks if proper precautions are not taken. It’s crucial to prioritize safety during every stage of the sandblasting process to prevent injuries and ensure a healthy working environment.

Potential Hazards

Sandblasting involves high-pressure air that propels abrasive materials, such as sand or glass beads, at a high velocity. This process can create a number of hazards, including:

- Respiratory Problems: Inhaling sandblasting dust can lead to serious respiratory issues like silicosis, a lung disease caused by inhaling silica dust. This condition can cause shortness of breath, coughing, and chest pain.

- Eye Damage: Sandblasting particles can cause severe eye injuries, including corneal abrasions, scratches, and even blindness.

- Skin Irritation: Prolonged exposure to sandblasting dust can irritate the skin, leading to dermatitis, rashes, and other skin problems.

Essential Safety Equipment

To mitigate these risks, it’s essential to use appropriate safety equipment:

- Respirator: A respirator with a HEPA filter is crucial for protecting your lungs from dust particles.

- Safety Glasses: Wear safety glasses or goggles with side shields to protect your eyes from flying debris.

- Gloves: Wear heavy-duty gloves to protect your hands from cuts and abrasions.

- Dust Mask: Use a dust mask to filter out any airborne particles that may escape your respirator.

- Hearing Protection: Sandblasting can be loud, so wear earplugs or earmuffs to protect your hearing.

Setting Up a Safe Work Area

A well-equipped and organized work area is essential for safe sandblasting:

- Ventilation: Adequate ventilation is crucial for removing dust and fumes from the work area. This can be achieved using a powerful exhaust fan or by working outdoors in a well-ventilated space.

- Lighting: Ensure sufficient lighting to clearly see the work area and avoid accidents.

- Designated Workspace: Designate a specific area for sandblasting, away from any flammable materials or electrical equipment.

Minimizing Dust and Debris

Several techniques can help minimize dust and debris during sandblasting:

- Dust Collector: Using a dust collector connected to the sandblasting cabinet can capture a significant amount of dust.

- Wet Blasting System: Wet blasting systems use a mixture of abrasive material and water, reducing dust generation.

- Sandblasting Enclosure: Enclosing the sandblasting area can contain dust and debris, making cleanup easier.

Disposal of Used Sandblasting Media and Waste Materials

Proper disposal of used sandblasting media and waste materials is crucial for environmental protection:

- Used Sandblasting Media: Dispose of used sandblasting media in a designated container or according to local regulations.

- Waste Materials: Dispose of waste materials, such as sandblasted parts, in accordance with local regulations.

Building a DIY sand blast cabinet is a great way to give old items a new lease on life. But what good is a beautifully refinished piece if you don’t have a place to display it? That’s where a corner bar cabinet with fridge comes in handy.

Imagine your freshly sandblasted treasures nestled in a stylish corner bar, ready to be admired. With your DIY sand blast cabinet and a chic bar cabinet, you’ll be the envy of all your friends.

Building a DIY sandblast cabinet is a fun and rewarding project, allowing you to give your creations a professional finish. But just like a well-stocked bar needs a sleek and functional flip top bar cabinet , your sandblast cabinet should be designed with efficiency in mind.

A well-organized space for your tools and materials makes the whole process smoother and more enjoyable. So, let’s get those creative juices flowing and build a sandblast cabinet that’s as practical as it is cool!